Epoxy vs Chrome shelving – which is best for you?

For both businesses and homes, wire shelving units are a visually appealing and cost-effective choice. Because of their longevity, flexibility, and high load size, chrome and epoxy wire shelving units are the most common. However, determining which solution is better for you can be difficult. When shopping for shelving units, it’s crucial to remember and determine your primary need for the product before deciding which choice is better for you. When selecting racking, keep the following factors in mind:

· Load capacity – what is going to be stored on the shelf?

· Environment of your space, cold, dry/wet, outside / inside?

· Size /shape of the room – e.g. display, coolroom, garage

· Assembly – can i do it myself?

So what’s the difference?

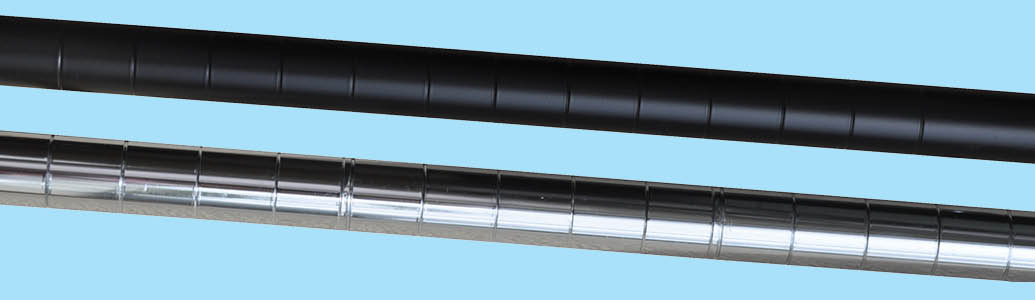

Chrome Wire Shelving

Chrome Wire Shelving

Although chrome shelving is normally the more costly choice, it is widely regarded as the most aesthetically appealing. The smooth texture and shiny silver surface are the main reasons for this. The poles that reside inside the shelving add to the streamlined look by making a streamlined appearance. Chrome shelving is suitable for places where it would be on sale, such as showrooms or department shops, because of this. They’re also popular in a variety of commercial settings, including storerooms, kitchens, and offices. Chrome shelving is not only attractive, but it is also very well-made and durable. It’s also worth remembering that chrome shelving is only appropriate for dry conditions with no humidity or dampness.

See the Brayco range of chrome shelving here.

Epoxy Wire Shelving

Epoxy shelving is less expensive and has a sleeker appearance than chrome shelving. It has a temperature range of 0°C to 300°C and can be used in both wet and dry conditions, making it very flexible. Water resistance is provided by the rubberised coating, which also protects against rust and corrosion. Epoxy is ideal for conditions that are rainy, cold, humid, or have frequent temperature fluctuations. Coolrooms, garages, sheds, food storage, and warehouses are only a few of the places where epoxy shelving systems are often used. Epoxy also helps to inhibit the growth of bacteria, making it a germ-free storage alternative. Furthermore, epoxy is chemically resistant, which is essential in the food service industry where a variety of chemicals are used.

See the Brayco range of epoxy shelving here.

What do you need to consider before making a purchase?

LOAD CAPACITY

Both chrome and epoxy shelving have the ability to be durable, but the strength of each brand varies greatly. When purchasing shelving, keep in mind the load capacity of each shelf as well as the thickness of the steel used. It is worthwhile to compare brands; even though they seem to be identical at first glance, a closer inspection will reveal a disparity inconsistency.

(We’d like to point out that Brayco uses a thicker diameter of steel than other rivals, making them very durable and capable of carrying 150kg per shelf.) It is also vital to remember, as with any shelf device, that the weight is spread uniformly around the shelf to prevent undue tension on the shelf and for protection when used with larger loads storage.

ENVIRONMENT

Choose epoxy shelving with a rubberised coating if you have a lot of moisture or a cool room. These are ideal for garages, coolrooms, and even places like a bottle shop or wine cellar.

Since certain floors are uneven, flexible feet are a handy function that will ensure the shelving’s maximum stability.

Are you looking for a portable unit? Castors are a good option. This provides flexibility and portability, but at the expense of total load size, so think about the use and suitability before going mobile. It’s ideal for storing table linen that can be transferred from the dining room to the storage/delivery unit. Alternatively, with pool towels that can be wheeled indoors at the end of the day, use an epoxy device.

LOCATION / SHAPE OF THE ROOM

With the latest S hook accessory, this shelving can be conveniently customised to each customer’s room and needs. For more room and easier access, create straight, L, or U configurations with no corner posts. No end poles are required; simply attach the S hook onto the end of each shelf and hang the next shelf onto it. S hooks come in chrome and epoxy finishes to complement every form of shelving.

To prevent your load from sliding off the end of each bay, add shelf dividers to the end of each bay – a useful accessory to search for when selecting your unit.

ASSEMBLY

The ease of assembly is a distinct attribute of both chrome and epoxy units. A shelf can be placed anywhere along the length of the pole, and any number of shelves can be attached, thanks to the innovative clip shape.

These best-selling wire shelving packages provide anything you’ll need to easily expand your storage room (4 shelves included). Shelving units can be put together in a matter of minutes. You should get as many shelves as you like!

No tools are required; simply snap the black clips into place on the uprights, then drop the shelf over the clips and push them into place. The most difficult challenge would be ensuring that the four clips are at the same height such that the shelf is level; this is a simple workaround that can be accomplished by counting the strategically spaced grooves in the poles and ensuring that each clip is set at the same height.

Brayco offers a wide variety of sizes in both epoxy and chrome, ranging from 457 to 1524mm wide and 1800mm tall, with optional features such as castors, additional racks, s hooks, and shelf dividers.

For the full range of Brayco wire shelving including all sizes and pricing, click the link